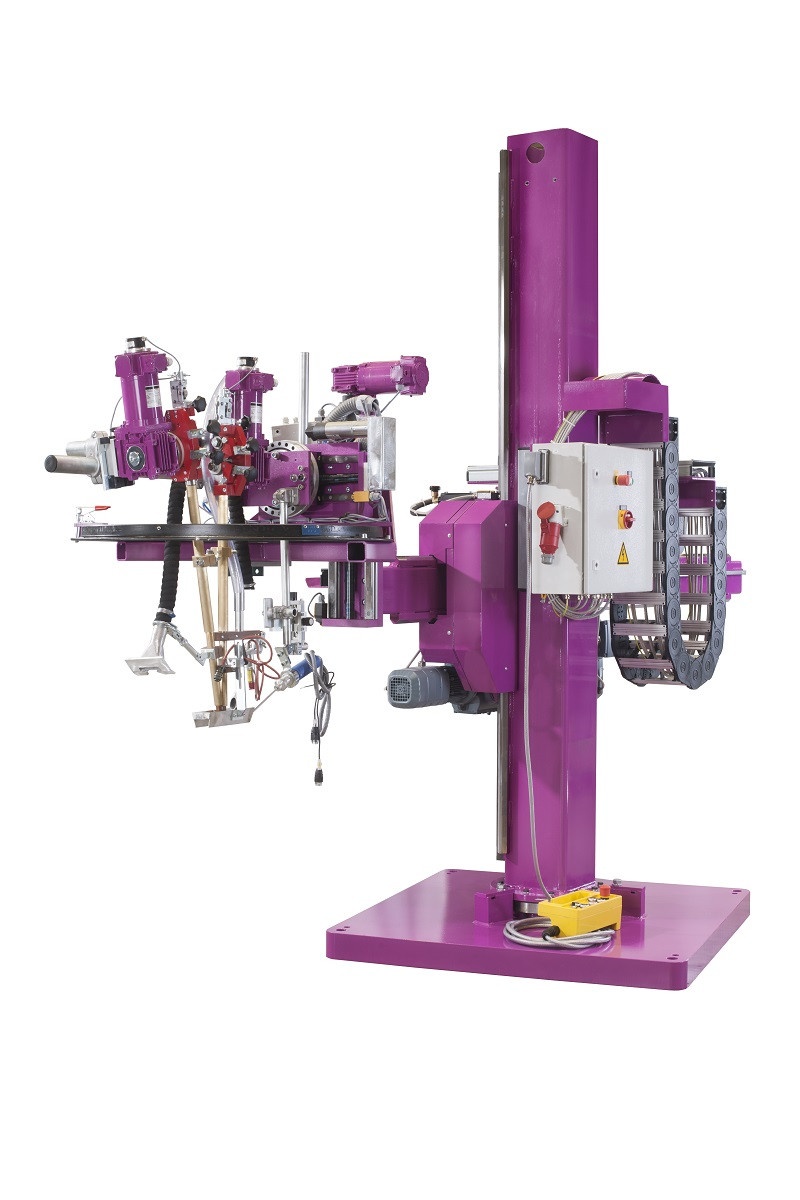

Designed to improve efficiency with no compromise to superior fabrication standards, Kistler Column and Booms stands tall in the world of welding. By virtue of their modular design, they offer flexibility and customized solutions for any unique task at hand.

Column and Boom welding machines can be a great aid in improving the accuracy, safety, and efficiency of the welding process. They are widely utilized in sectors like pipelines, heavy machinery, and shipbuilding. They can also be utilized to weld in locations that are difficult to access or in circumstances where using a human welder would be dangerous or unfeasible. A base, a vertical column or boom, and a horizontal boom make up a "Column & Boom" welding system. While the vertical column or boom stretches upward to support the horizontal boom, the base of the column and boom offers stability and support for the remainder of the machine. The welding torch can be positioned at the required spot by adjusting the horizontal boom.

Every welding column and boom welding manipulator that we produce is internally developed and built at our factory using premium parts. Because of its modular design, Kistler Column & Booms can be easily customized to meet any requirement the customer may have for welding work, regardless of the specific welding technique, the material being used, or the geometry of the created goods. The following techniques can be used with Kistler column and boom welding manipulators: TIG, SAW (single, twin, tandem, and multi-arc), GMAW and cladding made of strips or wire.

Technology

Our Column & booms welding Manipulators are designed to enhance performance and fulfil premium manufacturing standards. The foundation of our column and booms is an intuitive control mechanism. The system stores all necessary welding programs for future use, gives precise process reports, and facilitates total control over the C&B from a single touch screen.

To get the most from the device's productivity, factors such as wire reel size and

position, welding tools, cross slide, welding head mounting, flux management in the case of SAW, and seam tracking technique are taken into consideration together with its dimensions. Our column and booms come in the following models:

Features of Column and Boom Welding Manipulators

1. 360° column rotation with manual locking at any position

2. Boom elevation through the geared motor rack and pinion drive with electro-magnetic brake.

3. Optional fittings, including welding heads available.

4. Variable speed boom.

5. Elevation and traverse drive mounted on saddle providing for easy access servicing and maintenance.

6. Machines fully counter-balanced by column internal weight, connected to the saddle by heavy-duty wire rope. The anti-fall device offers a full safety feature.

7. Extra wide rollers and unique slideways ensure minimum deflection traversing.

8. Innovative machined ‘V’ ways to column ensure that the boom saddle moves smoothly with no vibration. This reduces wear and tear