For the past 50+ years, Kistler has been designing and manufacturing welding positioners for difficult and large workpiece welding.

With the use of welding positioners, a welder can operate continuously on a level surface while standing still. Because the welder won't have to keep moving around the workpiece to finish the weld, worker fatigue will be prevented, and productivity will rise. Since there are no overhead or vertical runs involved, this manner of presenting the workpiece also tends to guarantee consistently high-quality welds.

Enhanced Productivity

Positioning a workpiece in the ideal position for safe and efficient welding is the primary function of a welding positioner. Kistler welding positioners improve quality, productivity, and working flexibility. Positioners help welders do their jobs more effectively by providing a safer and more ergonomic work environment.

Workpieces can always be positioned for optimal welding positions, thanks to Kistler welding positioners, which is its primary benefit. Consequently, productivity gains in welding might reach up to 70%.

Our welding positioners seamlessly connect with other systems, combining a contemporary aesthetic with dependable, effective technology.

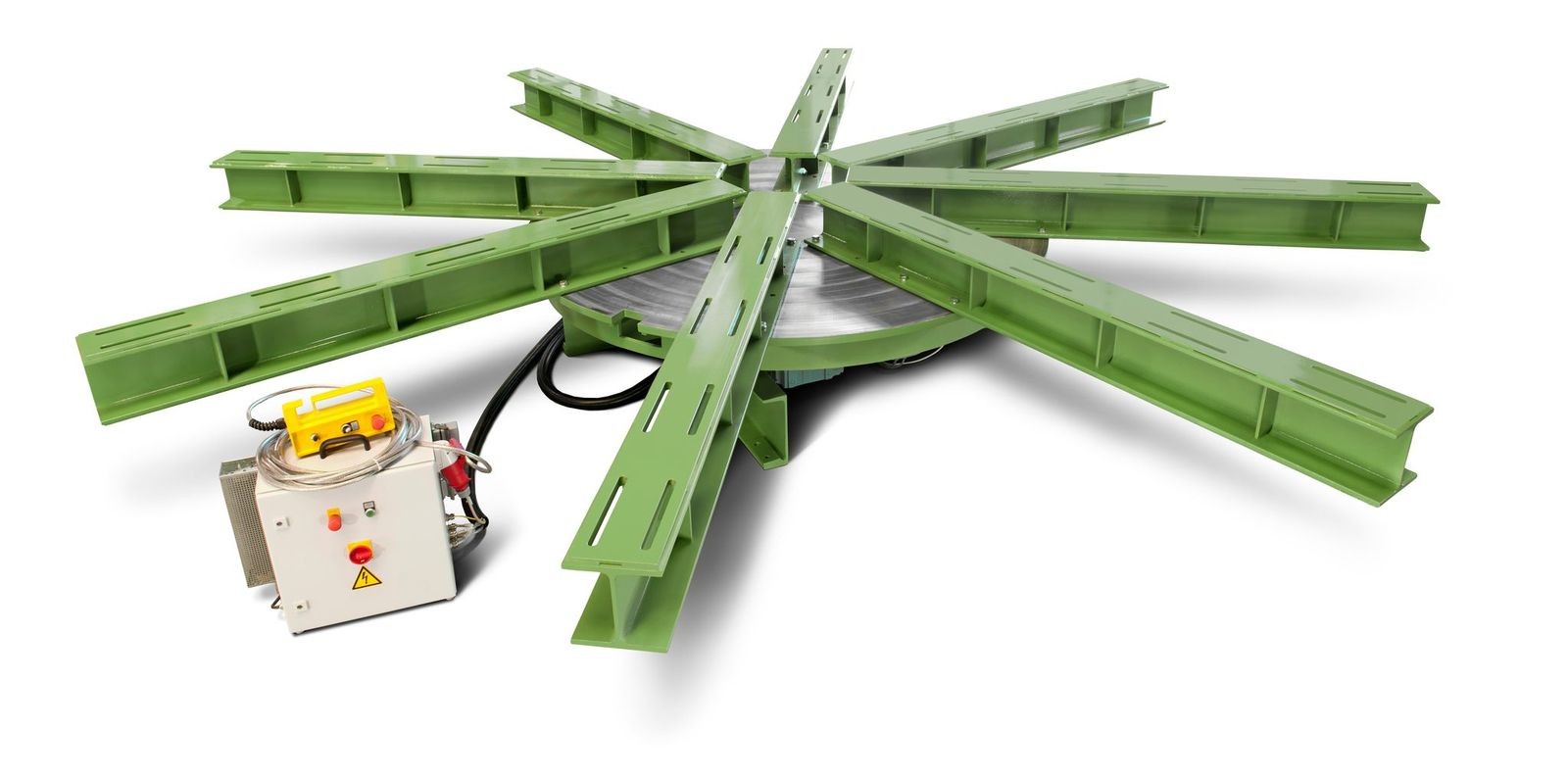

Positioners offer a flexible and efficient way for steel fabrication operations to position heavy fabrication jobs in the "downhand" orientation. As a result, handling time and crane usage are reduced.

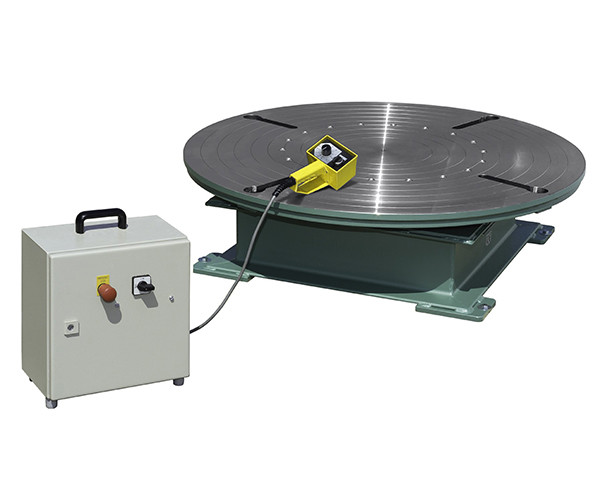

The positioners table can be readily utilized for a variety of tasks, including downhand position welding, saw and strip cladding, circumferential welding, and the assembly of delicate assemblies. It rotates at precise and constant variable speeds and tilts with a high C.G. load rating.

Many businesses are using welding positioners to minimize the amount of trail needed to process and retrieve items, as well as the number of times a part needs to be physically repositioned. Since a welding positioner spins the workpiece at a controlled rate and speed to maintain a continuous, penetrating weld, it solves a lot of problems with poor weld quality.

Kistler's Welding Positioners are a fast and efficient way to set up jobs for simple access to complex assemblies, strip cladding, down-hand position welding, and many other applications. Businesses that have purchased Kistler positioners have seen a drop in maintenance costs to less than 1% and an increase in pipe welding productivity. Our clients are becoming more competitive in their job bids as a result, and their profit margins on previously awarded contracts have grown. Our models are available in the following models: