-11692448958.jpg)

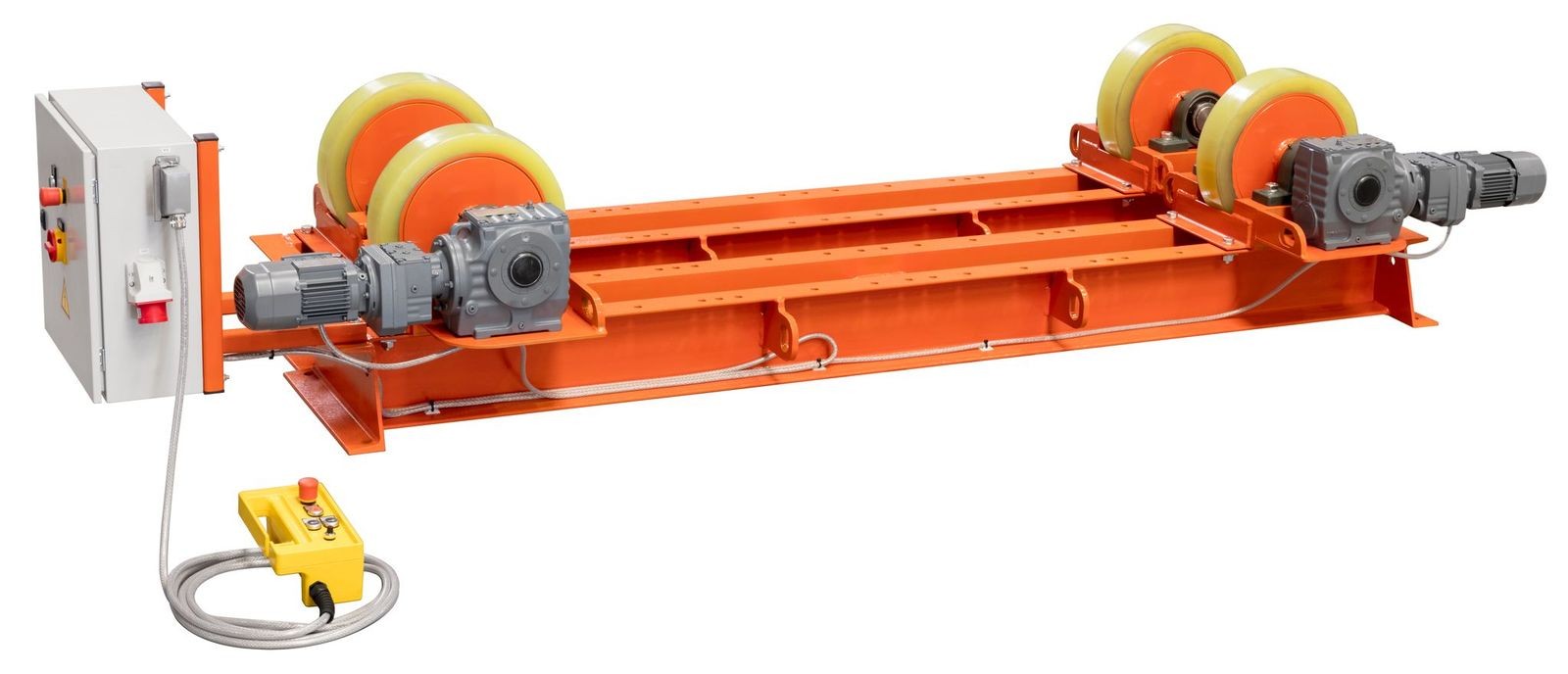

An industry-leading range of turning rolls, both for pipes and pressure vessels, designed and produced by Kistler, provide accurate rotation of cylindrical weldments for positioning in heavy manufacturing. Better throughput, safety, low maintenance, and a prolonged service life are the outcomes of this. Our wide range of turning roll designs and capacities is intended for particular uses, such as the manufacture of tanks, pressure vessels, tank cars, and pipe spooling.

Our skilled engineering staff will assess the load capacity, production process, and particular material attributes before recommending the best positioning option for your needs. Although standard products are the most common usage for our turning rollers, we also custom-engineer and integrate them with welding solutions for special applications that demand altered functionality.

Welding turning rolls can be mounted on a bogie or in a stationary configuration. The wheel distance suitable for various diameters can be adjusted manually or with the use of a manual or motorized spindle adjustment. We can also provide you with self-adjusting turning rolls as an alternative.

The turning rolls can be fitted with an anti-drift mechanism to stop the pipe from drifting or creeping off.

The welding turning rollers can be supplied as full systems for use with a welding gantry or a column & boom manipulator.

At Kistler, every element is meticulously synchronized to provide the best possible production outcomes. Cylindrical vessel rotating and handling problems can be addressed economically and practically with Kistler's conventional & self aligning welding turning rolls.

Tank Turning rolls are a mechanical way to rotate cylindrical vessels, just like rotators and positioners . They reduce handling, boost productivity, and significantly raise the caliber of work produced by welders of all experience levels. Kistler offers both conventional and self-aligning rotators to accommodate different weldment sizes in a range of industries. A rotator is useful and occasionally required in any steelworks with cylindrical vessels, whether they are tiny diameter pipework or massive industrial cylinder vessels for the manufacturing of wind towers. A rotator is essential for most welding processes such as SAW, TIG and MIG if the weldment is cylindrical.